BMM construction photo journal

Table of Contents

- Hutch construction webcam images, December 23, 2015

- May 19 2017

- May 17 2017

- May 16 2017

- May 15 2017

- May 12 2017

- May 10 2017

- May 9, 2017

- December 20, 2016

- December 16, 2016

- December 14, 2016

- November 15, 2016

- November 8, 2016

- October 18, 2016

- October 6, 2016

- October 3, 2016

- September 16, 2016

- June 17, 2016

- May 10, 2016

- May 5, 2016

- April 29, 2016

- April 21, 2016

- April 13, 2016

- April 5, 2016

- December 22, 2015

- December 14, 2015

- December 8, 2015

- December 2, 2015

- December 1, 2015

- November 23, 2015

- November 10, 2015

- November 9, 2015

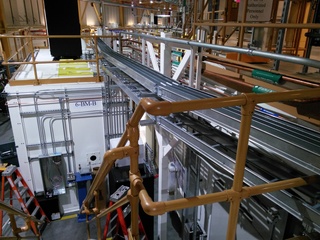

Hutch construction webcam images, December 23, 2015

| B hutch | A hutch |

|

|

Last hutch construction video (avi format, 9.6 MB). This includes snapshots from Nov 30 through Dec 7, 2015 and runs about 1 minutes 19 seconds. The soundtrack is a Yakety Axe, a Chet Atkins arrangement for steel guitar of Yakety Sax (which many know as the Benny Hill theme). This music is in the public domain.

May 19 2017

Today's big event was the unpacking and assembling of the optic for the focusing mirror (M2).

| The crate containing the optic and bender from SESO | M2 with the lid off, looking upstream | M2 with the lid off, looking downstream | The lid from M2, sitting on the floor |

|

|

|

|

The mono crystal cage was moved into position before work on M2 began.

| Hoisting the crystal cage around M2 | Fitting the cage onto the mono Bragg axis |

|

|

Prepping the mounting platform for the bender and optic….

| The mounting platform, removed from M2 | The actuators and kinematic mounts on M2 | Close-up of the downstream kinematic mounts |

|

|

|

A few hours later, Beau had the bender assembled and the optic in place. This is now ready for survey.

| M2 bender and optic, looking downstream | The downstream end of the bender | The upstream end of the bender | Looking upstream |

|

|

|

|

May 17 2017

May 16 2017

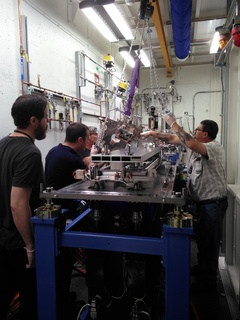

Today there has been some nice progress towards installation. Much of it is not very photogenic, but a lot is getting done.

In the first photo, Ian and Beau are lowering the mono off its wheels and onto its grouted plate.

| The mono is back in its home. Note DM1 just upstream | Travis is mostly done with cable pulling in the B hutch | Cables going upstream tothe XAS table | Signal and SHV cables |

|

|

|

|

| The filter assembly from DM1 | Filter assembly, up close | The Bremsstrahlung shield stand, installed |

|

|

|

May 15 2017

Diagnostic module #1

Bremsstrahlung shield

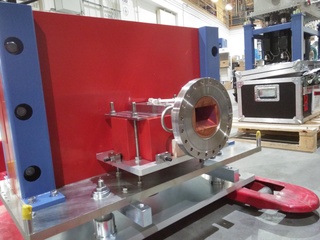

The Bremsstrahlung shield stand is the next component after the monochromator. Before it was picked up from the floor after last week's delivery accident, the shielding parts were removed from the stand. What you see below is the shielding, sitting on a pellet jack, waiting from installation.

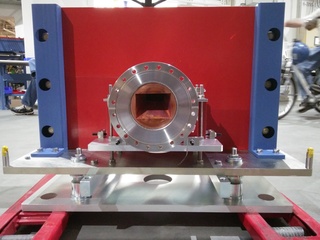

A new problem crops up. Notice below that the pink beam stop (the copper piece with the hole for the beam to pass through) is offset from the center of its flange. The flange was welded in place rotated by 180 degrees. The radiation safety bits are in the correct location, but the flange is offset in the wrong direction. This means that additional strain will be placed on the bellows connecting this to the monochromator.

The primary Bremsstrahlung shield is the thick, red-painted, lead block just below the beam pipe. The purpose of this component is to stop the high-energy gas Bremsstrahlung originating in the storage ring. Because we have an upward-deflecting mirror in the front-end, the pink synchrotron light enters the hutch above the primary Bremsstrahlung. Hence the primary Bremsstrahlung shield is below the X-ray beam path.

The copper bit is the pink beam stop. It's purpose is to stop the pink beam from t he front end mirror in the situation where the first monochromator crystal is, for some reason, removed from the beam. It is water-cooled – note the cooling line brazed into the copper and sticking out in the foreground.

The big red mass of lead is secondary Bremsstrahlung shield #2. The purpose of this is to catch Bremsstrahlung radiation which has scattered off of some component upstream, either in the A hutch or in the front end. Its large area is necessary to catch the full possible fan of such a scattering event.

| The pink beam stop | The primary Brem shield and secondary Bram shield #2 | The downstream exit of the Bremsstrahlung shield |

|

|

|

May 12 2017

Picking up the pieces

On May 11, the first diagnostic module and the Bremsstrahlung shield stand were delivered, along with several crates of smaller kit. Unfortunately, the two large crates containing those components toppled over in the back of the delivery truck. Here is a photo journal of the work of the BNL riggers extracting that mess from the back of the delivery truck.

Today, the riggers came back to pick up all the components.

The solution to having DM1 slide along the floor was very clever. The BNL riggers are awesome!

| Use a second fork lift to lift from the other side | Up, up, up… | Getting there… | Almost up, pull, Jimmy, pull! | And up! | Whew! |

|

|

|

|

|

|

Other activities

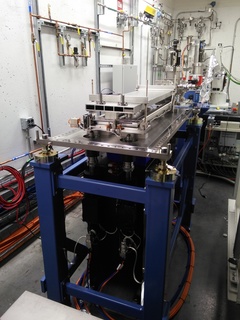

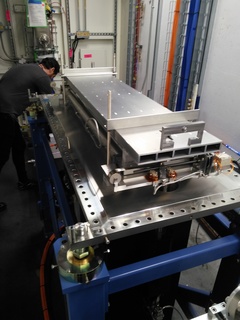

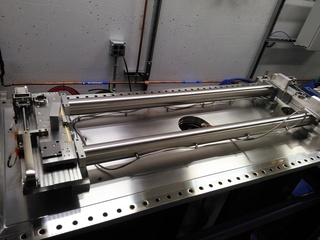

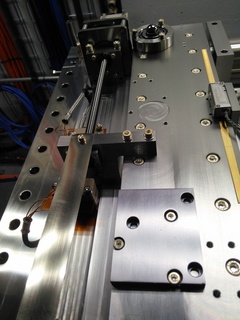

The new mono plate allows the mono to be translated laterally between sets of Si(111) and Si(311) crystals.

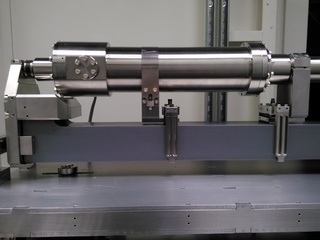

I love the photo of M3. It looks like a real beamline!

| Secondary Bremsstrahlung shield #1 (on DM1) | Lifting the new mono plate out of the crate | Laying the new plate on the granite plinth | Mirror M3, temporarily in place for cable fitting |

|

|

|

|

May 10 2017

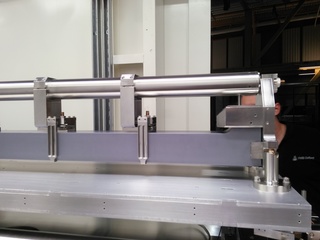

Ends of the transport pipe

May 9, 2017

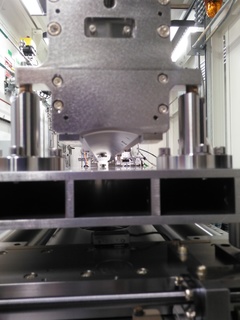

Monochromator

Uncooled fluorescent screen stand

Pump stand for the transport pipe

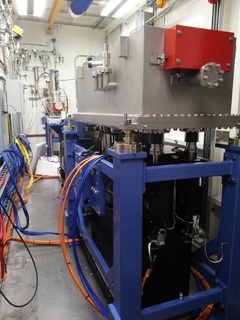

This stand supports a shielded box which holds an in-line ion pump. This, along with the pump on the fluorescent screen shown above, pumps out the transport line between the hutches.

| The holes don't quite line up with the holes in the floor | Art the rigger is waiting to lift the shielded box | Ian drills out the holes on the stand's legs | More drilling |

|

|

|

|

The box is then jockeyed into position on the stand. This thing weights a lot!

| Positioning | Lifting | Getting there | Close | Just about! |

|

|

|

|

|

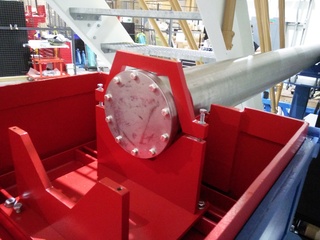

The pump vessel and the secondary stand are now ready for the transport pipe. The red-painted parts are lead, the blue are steel.

| Empty shielded box. | Secondary stand |

|

|

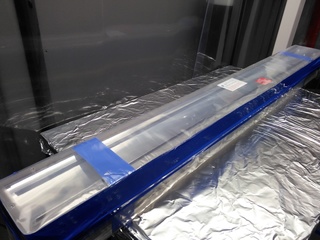

Transport pipe

This is a 6-inch steel tube with lead shielding wrapped around it. It weights about 370 kg/800 pounds.

| Remove the trasport from the shipping container | Carrying | Lifting |

|

|

|

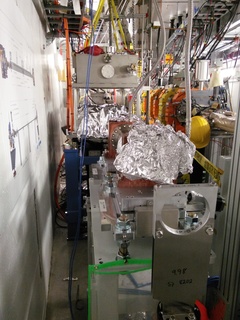

At this point, I had to run away to make a presentation about BMM to the Radiation Safety Committee. When I returned, the transport pipe was in place.

| Transport pipe protruding into the end station | Pipe resting on a collette in the shielded box | Ian and Beau work on attaching the lead collers to pipe | It was a difficult job |

|

|

|

|

December 16, 2016

The collimating mirror (M1) and the front end are being installed this week.

M1 installed in the front end

December 14, 2016

I went to the APS for a week of experiments. Upon my return A LOT of stuff had happened! M1 and front end installation also began. Photos to come.

FOE

November 15, 2016

November 8, 2016

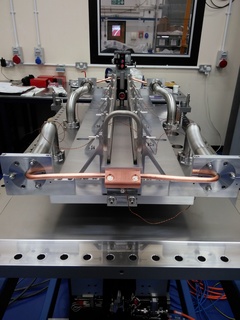

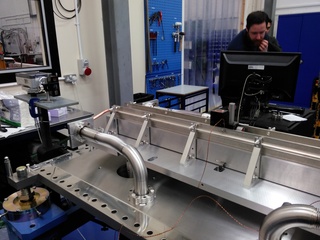

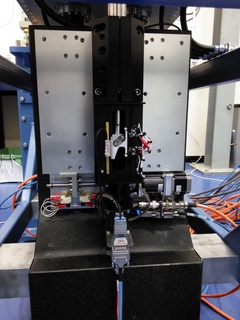

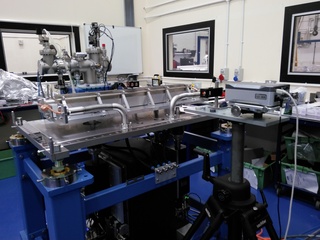

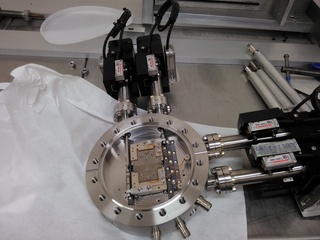

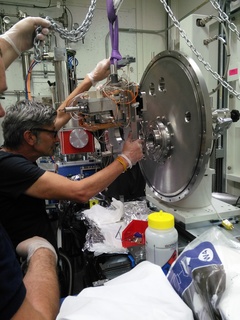

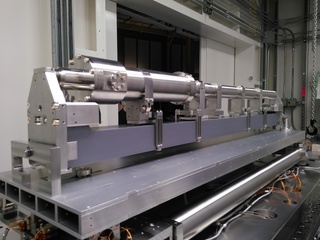

Factory acceptance testing at the FMB Oxford factory!

BMM Mirror 1

SST Diagnostic Modules

BMM M2 and M3 bake-out

October 18, 2016

October 6, 2016

October 3, 2016

June 17, 2016

May 10, 2016

May 5, 2016

April 29, 2016

April 21, 2016

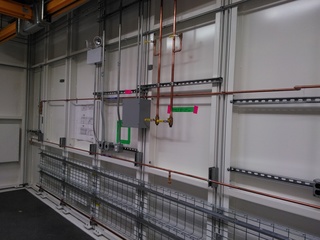

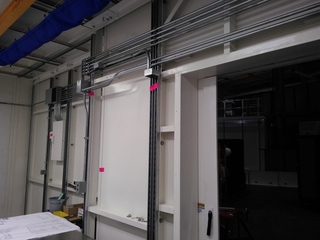

Progress on utilities installation has been amazing! The electricians and plumbers are doing bang-up work.

| 6BM-A utilities, inboard wall | PPS in 6BM-A | 6BM-B utilities, inboard wall | Electrical in 6BM-B | Racks awaiting installation | Plumbing on pylon 1 | Plumbing on Pylons 2 and 3 | Plumbing distribution, 6BM-B |

|

|

|

|

|

|

|

|

April 13, 2016

April 5, 2016

December 22, 2015

Just in time for a jolly, jolly holiday, Caratelli finished the BMM hutches. Look how lovely they are!

A hutch roof

December 14, 2015

December 8, 2015

Floor level views of the hutches

December 1, 2015

November 10, 2015

November 9, 2015

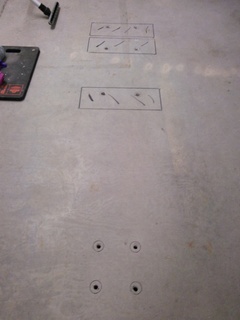

Construction begins on BMM. Hutch panels have been delivered, hutch boundaries are marked in ink on the floors, and door slots have been ground into the concrete.

| Construction begins | Slot for 6BM-B door | Slot for 6BM-A door | Parts for the 6BM hutches | 6BM-A wall panels | 4BM-B roof panels (ours will be similar) |

|

|

|

|

|

|